Experimental Research (expRES@IBK)

Research at IBK benefits from an excellent infrastructure, which is continuously being maintained and updated. We have access to high performance computing resources, both in-house and at ETH level (Euler cluster), and benefit from world-class facilities for large-scale structural testing. The Institute shares 5 compute nodes (120 cores) on the Euler Cluster. Some groups also have their own, local computing resources (e.g. 3 CPU and 1 GPU machine (96 cores) at the chair of Prof. Sudret).

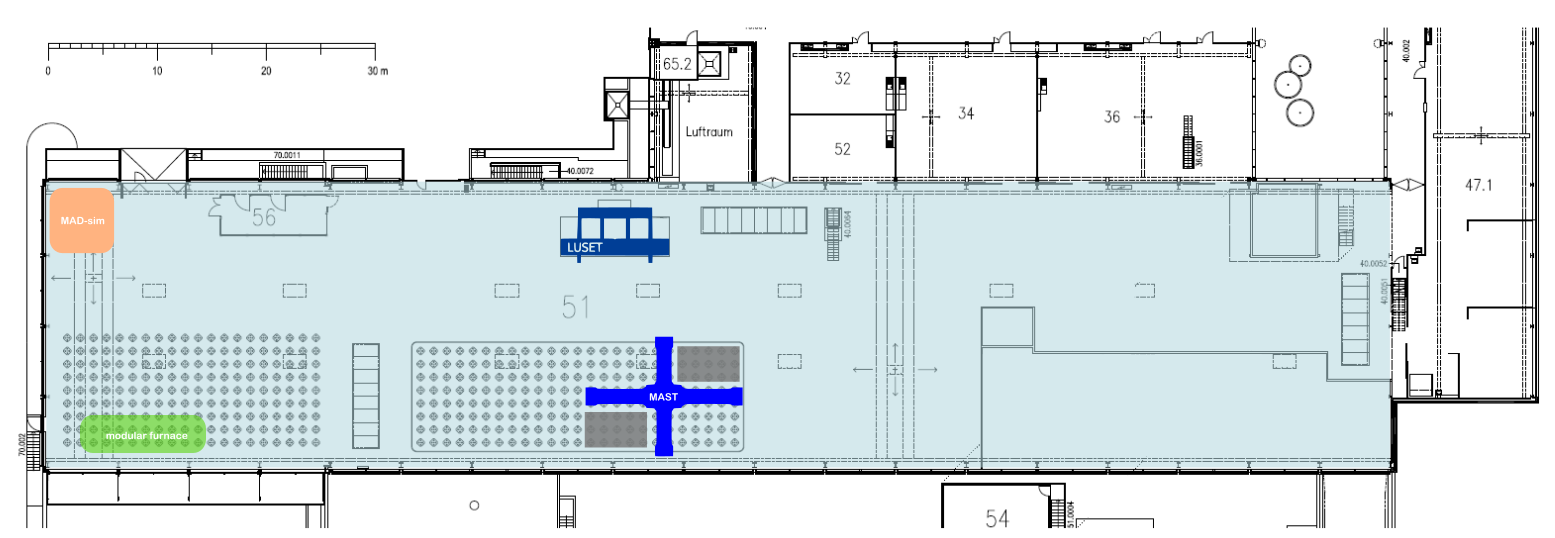

Experimental testing facilities

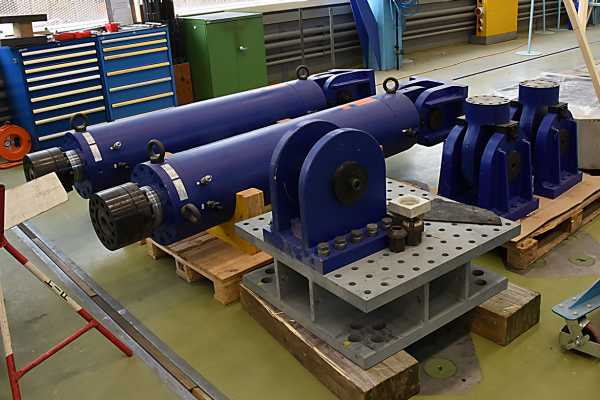

IBK directs D-BAUG’s laboratory for experimental research (Bauhalle) located in HIF C51 and is its main user. This laboratory, with a 125x30 m2 floor and 12 m height, is equipped with two overhead cranes (lifting capacity 10t each). It contains two 9.6x28.8 m2 and 10.8x24.0 m2 strong floors equipped with 192 and 180 loading points, respectively, with capacities of 1.5 and 2 MN in any direction each. Hydraulic power is provided by four pumps delivering 1x120 l/min and 3x250 l/min, respectively, all at an operating pressure of 280 bar. Individual test setups on these strong floors can be configured using a wide range of modular steel elements (“meccano system” consisting of reaction walls, columns, beams etc.). The laboratory operates numerous hydraulic actuators, with capacities ranging up to 4’000 kN. Test specimens are typically instrumented with several of the following devices:

- Three-dimensional optical laser tracking systems (NDI)

- High resolution three-dimensional and two-dimensional image correlation systems (VIC 3D, Correlated Solutions)

- Distributed fibre-optical strain measurement systems (LUNA, Rayleigh backscatter technology)

- A variety of load cells and pressure sensors

- A variety of conventional LVDT’s, deformeters (partly wireless)

- A variety of accelerometers and tilt meters

- Acoustic emission sensors

The laboratory also hosts two Universal Testing Machines for tensile and compressive testing up to a capacity of 1’600 kN and 480 kN, respectively, as well as a small shake table with dimensions of 1.0x2.0 m2 and a machine for tensile testing of timber boards up to a capacity of 850 kN. In addition, a modular electrical furnace consisting of 60 heating radiant panels with dimensions of 0.56x0.56 m2 allows testing large specimens at high temperature. A concrete cutting and grinding facility and various mobile lifting equipment (forklift, lifting ramp, etc.) complement the installations. Furthermore, the concrete production plant and a variety of smaller testing machines, located in the basement and operated by the Institute for Building Materials (IfB), can also be used.

Besides the above-mentioned “standard” equipment, our experimental testing facilities have been significantly enhanced in the period 2014-2019 through several innovative setups:

- Multi-Axial Subassembly Testing system MAST, Prof. Stojadinovic

- Large Universal Shell Element Tester LUSET, Prof. Kaufmann

More information on experimental equipment can be found in the IBK inventory database.